Bottle Positioning and Separating System

Page Detail

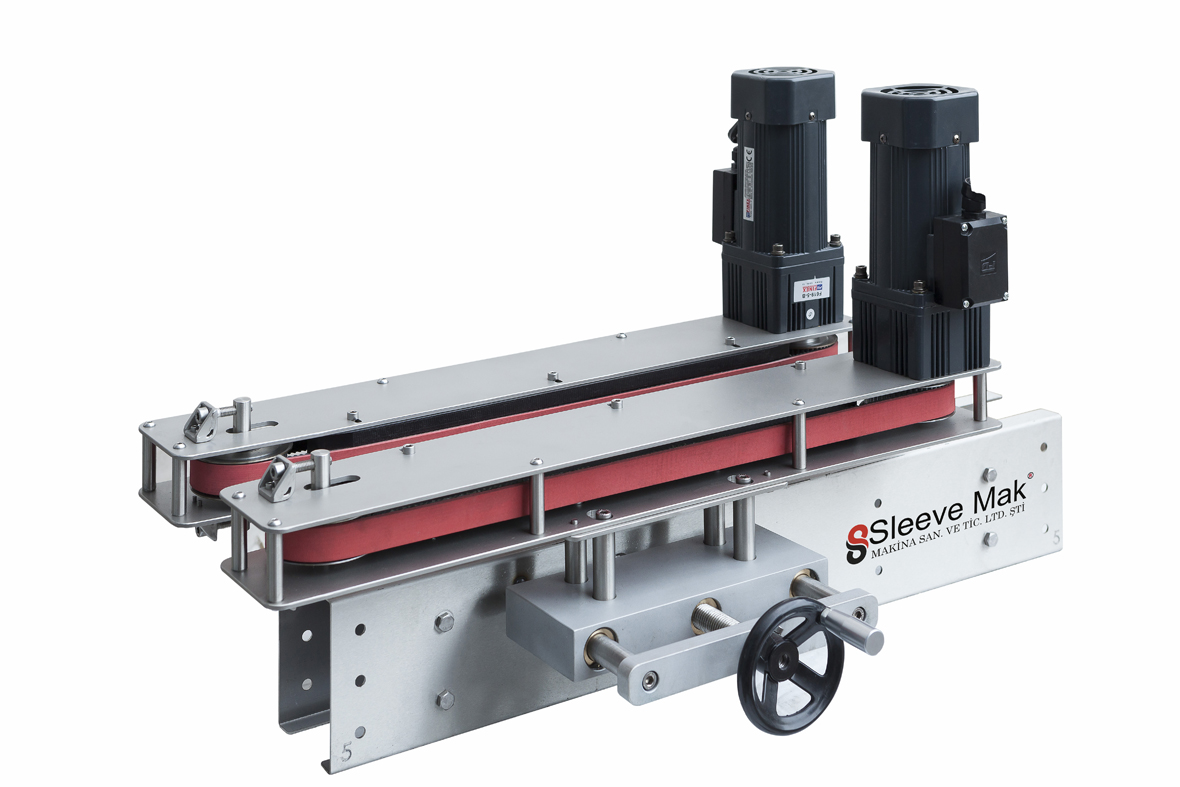

Bottle Positioning and Separating System

Bottle Positioning and Separation System

- Model: SVM-S001

The construction of the system is made of stainless steel AISI 304 and aluminum materials. It has the ability to work in synchronization with a sleeve machine. It is equipped with 1 reducer motor (180 Watts). The speed can be adjusted with an electric drive.

Note: The term "sleeve machine" refers to a type of equipment used for labeling bottles with shrink sleeves, which are plastic labels that shrink and conform to the shape of the bottle when heat is applied. The bottle positioning and separation system mentioned here likely works in conjunction with a sleeve machine to ensure proper alignment and separation of bottles during the labeling process.

-

Bottle Positioning: The process of placing bottles in a specific order or position. This can be done through automated systems on a production line or manual operations.

-

Separating System: A system used to separate or group bottles. These systems typically operate based on capacity, size, or shape.

-

Automatic Separation: The method of bottle separation that utilizes automated systems such as machine vision or sensor technology.

-

Manual Separation: The process of manually separating bottles according to a specific sequence or grouping.

-

Steam Tunnel: A method of heating and drying bottles using steam, commonly used in manufacturing processes or industrial applications.

-

Production Line: A system that encompasses a series of operations for bottle manufacturing or filling. The bottle positioning and separating system can be a part of a production line.

-

Efficiency: A factor related to the fast and accurate operation of the bottle positioning and separating system. Efficiency can contribute to process improvement and cost savings.

-

Industrial Applications: The bottle positioning and separating system is widely used in industries such as food and beverage, pharmaceuticals, cosmetics, and similar sectors.

-

Automation: The bottle positioning and separating system can be integrated with automation solutions such as automated control systems and robotics, reducing human intervention and enhancing operational continuity.

-

Quality Control: The bottle positioning and separating system may incorporate quality control mechanisms to ensure the accuracy and reliability of the positioning and separation process.

Share

Product Information

| Size: | |

|---|---|

| Colors | |

| Material |

Sleevemak Machinery Industry